Fire Safety and FRP Cable Trays: Meeting Regulatory Standards

Fire safety is a paramount concern in buildings and industrial facilities. Adequate fire protection measures are not only essential for the safety of occupants but also for safeguarding critical infrastructure, including electrical systems. Fiber Reinforced Polymer (FRP) cable trays have gained popularity due to their lightweight, corrosion-resistant properties, but ensuring they meet regulatory fire safety standards is crucial.

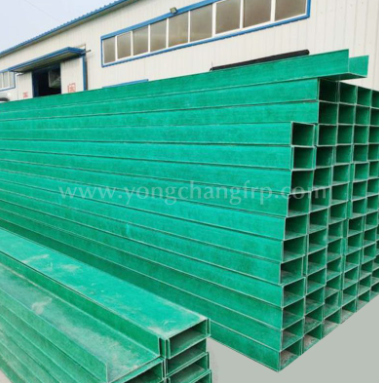

Understanding FRP Cable Trays

FRP cable trays are constructed from composite materials, typically a combination of fiberglass and resin. They offer several advantages, including corrosion resistance, electrical insulation, and lightweight design. However, these benefits must be balanced with compliance to fire safety regulations.

Fire Safety Regulatory Standards

Fire safety standards vary by region and application, but they generally focus on the following key aspects:

Flame Spread and Smoke Generation: Regulations often dictate the maximum flame spread and smoke generation allowed for materials used in construction and electrical systems.

Fire Resistance Ratings: Certain applications, such as those in fire-rated enclosures, require materials to meet specific fire resistance ratings, typically measured in hours.

Toxicity and Off-Gassing: The toxicity of materials when exposed to fire is a critical concern. Regulations may limit the release of toxic gases and chemicals during combustion.

Ignition Temperature: Materials used in critical areas should have high ignition temperatures to resist catching fire.

Meeting Fire Safety Standards with FRP Cable Trays

Flame Retardant Additives: Manufacturers can incorporate flame retardant additives into the resin used to make FRP cable trays. These additives help reduce flame spread and smoke generation, aligning with fire safety requirements.

Fire-Resistant Coatings: Applying fire-resistant coatings to FRP cable trays can enhance their fire resistance. These coatings can withstand higher temperatures and protect the tray's structural integrity.

Material Selection: Choose FRP cable trays that are specifically designed and certified for fire-resistant applications. These trays are engineered to meet fire safety standards.

Regular Inspections: Conduct regular inspections to ensure that FRP cable trays are not damaged or compromised. Damaged trays may not provide the necessary fire protection.

Proper Installation: Follow manufacturer guidelines and industry best practices when installing FRP cable trays. Proper installation is crucial for maintaining fire safety integrity.

FRP cable trays offer numerous benefits, but ensuring they meet fire safety standards is essential for any application where fire safety is a concern. By choosing fire-resistant FRP cable trays, incorporating flame-retardant additives, and following proper installation and maintenance procedures, you can confidently use FRP cable trays while meeting or exceeding regulatory fire safety requirements. Prioritizing fire safety not only protects your infrastructure but also the safety of occupants in buildings and facilities.

555

0

0

Comments

All Comments (0)