Does Welded Wire Mesh Rust? What Are the Disadvantages of Welded Wire Mesh?

Feb. 20, 2024

Yes, welded wire mesh can rust, especially if it is made of carbon steel and not properly maintained. While welded wire mesh offers numerous benefits in construction, agriculture, and other industries, it is essential to understand its potential drawbacks to make informed decisions about its usage.

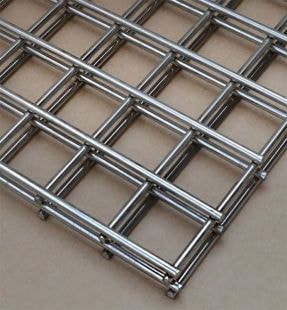

Welded wire mesh is a versatile material consisting of intersecting wires welded together at their intersections. It is commonly used for reinforcing concrete, creating fencing, animal enclosures, and various other applications due to its strength and durability. However, the welding process can impact the material's susceptibility to rust, particularly when carbon steel is used.

The primary disadvantage of welded wire mesh is its susceptibility to corrosion, especially in environments with high moisture or exposure to chemicals. Carbon steel welded wire mesh is particularly vulnerable to rust formation, which can compromise its structural integrity over time. This can lead to potential points of failure, posing safety risks in construction and other applications.

Another disadvantage of welded wire mesh is its limited flexibility compared to other materials like woven wire mesh. Welded wire mesh is less suitable for curved or irregular surfaces, limiting its versatility in certain applications. Additionally, the welding process can introduce structural weaknesses, making the mesh more prone to damage under stress or pressure.

Related links:Welded Wire Mesh Panels for Ultimate Security and Versatility

How do I change the filter on my Graco?

Disc Springs for High Load Applications: A Comprehensive Exploration

Classification and Application of Hexagonal Wire Mesh

Which Is Better? — Screw Compressor VS Piston Compressor

Everything You Need To Know About Pipe Clamps

Copper Clad Steel Round vs. Copper Clad Steel Flat

Cost considerations are also important when considering the use of welded wire mesh. While it is relatively affordable compared to other materials, the cost of corrosion prevention measures or maintenance should be factored into the overall expenses. Regular inspections, proper installation techniques, and surface treatments such as galvanization or epoxy coatings can help mitigate the risk of rust formation and prolong the lifespan of the mesh.

Despite these disadvantages, welded wire mesh remains widely used in various industries due to its strength and versatility. In the construction industry, it is used for concrete reinforcement, fencing, and partition walls. In agriculture and farming, it is employed in animal enclosures, poultry cages, and crop protection. Welded wire mesh also finds applications in concrete reinforcement, enhancing the strength and durability of structures like roads, bridges, and buildings.

In conclusion, while welded wire mesh offers numerous benefits, it is not without its drawbacks. Understanding the potential for rust formation and other disadvantages is crucial for ensuring the effective and sustainable use of welded wire mesh in various applications. By implementing proper maintenance and prevention measures, the disadvantages can be mitigated, allowing for the safe and efficient utilization of this versatile material.

The Advantages of Employing Composite Clad Plate

Composite Clad Plate vs. Traditional Steel: A Game Changer?

Key Considerations to Keep in Mind When Choosing a Sustainable Energy Provider

Copper Clad Steel Sheet vs. Solid Copper: Which Is Better?

Hot Rolling Clad Head vs. Traditional Steel: Key Differences Explained

The Advantages of Choosing Nickel Clad Steel

Nickel Clad Steel vs. Stainless Steel: Which is Better?

323

0

0

Related Articles

-

162

0

0

-

170

0

0

-

173

0

0

-

188

0

0

-

137

0

0

-

158

0

0

-

167

0

0

-

149

0

0

Comments

All Comments (0)